many friends will be torn when planning outdoor gas pipelines - can PE pipes be used to transport outdoor gas? After all, gas safety cannot tolerate sloppiness, and choosing the wrong material may bury hidden dangers. Today we will explain this problem thoroughly from the three dimensions of PE pipe characteristics, application advantages and precautions.

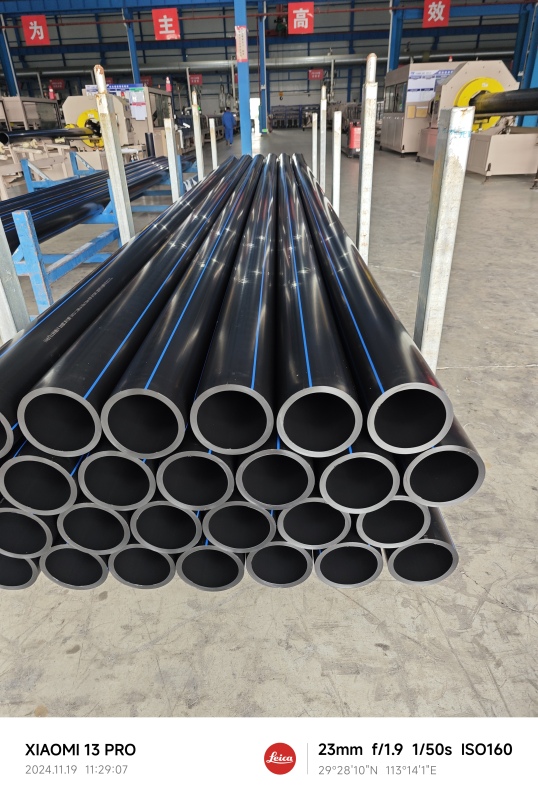

PE pipe, the full name of polyethylene pipe, is a kind of plastic pipe material with outstanding performance, and its core characteristics just match the needs of outdoor gas transportation: first, corrosion resistance - buried pipes will come into contact with acid and alkali substances in the soil, microorganisms, steel pipes are prone to rust and corrosion, cast iron pipes will be blocked due to rust, and PE pipes are completely "immune" to these problems and can keep the inner wall smooth for a long time without affecting the efficiency of gas transportation; secondly, flexibility is good - outdoor ground will inevitably settle, vibrate and even slightly geological changes, PE pipes can be "adjusted with the shape", unlike rigid pipes, which are easy to break, greatly reducing the risk of leakage; and reliable sealing - PE pipes are connected by hot melt or electric fusion, and the interface can be integrated, completely avoiding the common problem of traditional pipes "running and dripping", which is not good for burning Gas delivery is a crucial safety guarantee.

Because of these characteristics, PE pipes are particularly suitable for outdoor gas pipelines, and the specific advantages are obvious: first, long life - the design life of PE pipes for gas can reach more than 50 years, which is more durable than most metal pipes; second, convenient construction - PE pipes are light in weight, can be transported without large equipment, and the hot melt connection process is simple, which can save construction time and cost; third, low maintenance cost - due to corrosion resistance and not easy to leak, there is almost no need for frequent maintenance in the later stage, reducing maintenance troubles.

However, the use of PE pipes for outdoor gas is not "casually used", and several precautions must be followed: First, choose the right grade - be sure to use gas-specific PE pipes (such as PE80 or PE100 grade), these grades of PE pipes have been specially tested for gas transportation, and their pressure and penetration resistance meet national standards; secondly, match the pressure - choose the corresponding PE pipe according to the gas transmission pressure, such as SDR11 series for low-pressure gas, SDR17.6 series for medium pressure, and cannot be used under overpressure; thirdly, standardize the installation - buried at least 1.2 meters deep to avoid vehicle rolling or construction damage; add steel casing or concrete casing when passing through roads and ditches; there can be no sharp stones around the pipeline to prevent puncture; fourthly, regularly test - even if the PE pipe is durable

In general, PE pipes can be used for outdoor gas transportation, and they are currently the preferred material in many regions at home and abroad. As long as you choose the right gas-grade PE pipes and install and maintain them strictly according to specifications, you can safely and stably transport gas, and it will be fine for decades. Nowadays, many cities have replaced traditional metal pipes with PE pipes for outdoor gas pipes, which also proves its feasibility in practical applications. If you are considering the selection of outdoor gas pipes, PE pipes are a reliable choice.