In municipal drainage, construction and other pipeline construction, the acceptance process is a key step to ensure the quality of the project. Although the traditional closed water test can detect the sealing, it takes a long time, especially in the rainy season or when the construction period is tight, it is easy to affect the progress. With the wide application of HDPE carat pipe, the closed air inspection technology has become a new choice for acceptance due to its high efficiency and accuracy.

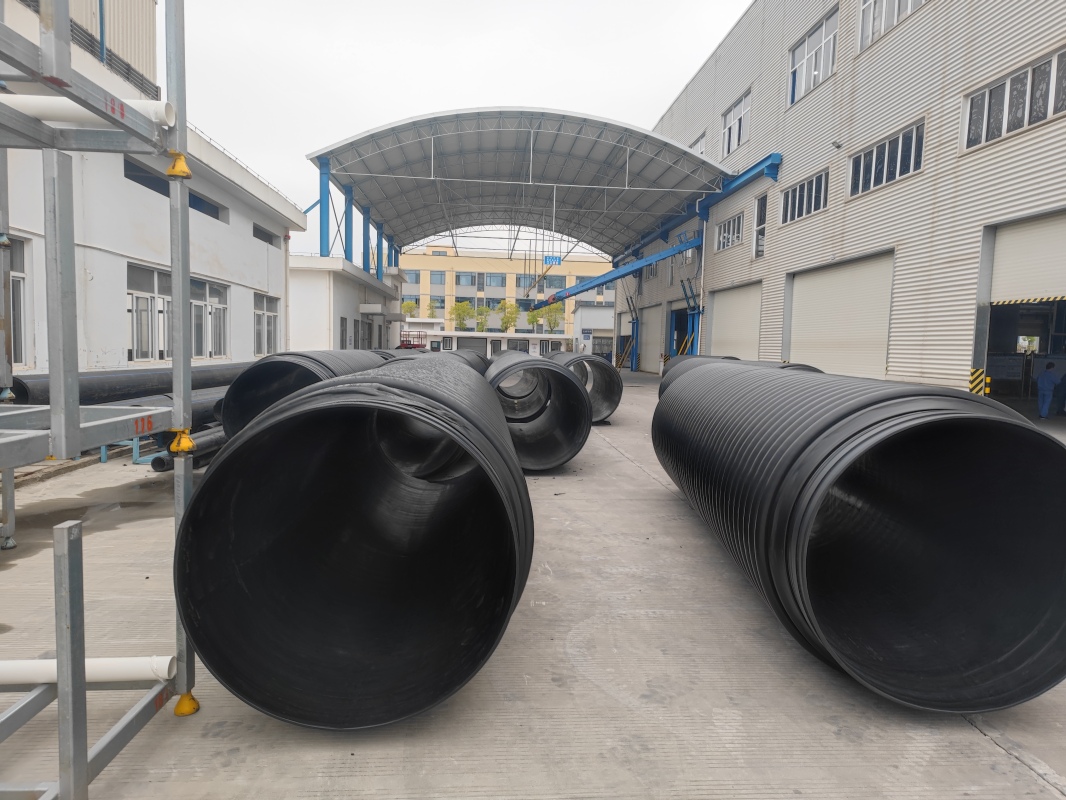

HDPE carat pipe is made of high density polyethylene, which has high strength, strong corrosion resistance and smooth inner wall. It is suitable for buried drainage and sewage system. Its reinforced rib structure design enhances the ring stiffness to meet the bearing requirements of different scenarios. The closed air inspection technology quickly judges the leakage by injecting compressed air into the pipeline and monitoring the air pressure change. The whole process only takes a few hours, saving more than 50% of the time compared with the traditional method.

As a benchmark in the pipeline industry, AD Pipeline always pays attention to product and technical suitability. AD HDPE carat pipe strictly controls the quality to ensure excellent sealing; cooperates with professional air-closing inspection tools and processes to make acceptance more convenient. The construction unit adopts this combination solution, which can shorten the cycle, reduce costs, detect problems in time to avoid rework, and ensure the smooth delivery of the project.

Whether it is municipal road rainwater discharge or community sewage pipe network, HDPE carat pipe with air-closing inspection technology is becoming the best project. Choose AD Pipeline HDPE carat pipe to make acceptance more efficient and quality guaranteed, and help the progress and quality of the project to improve.