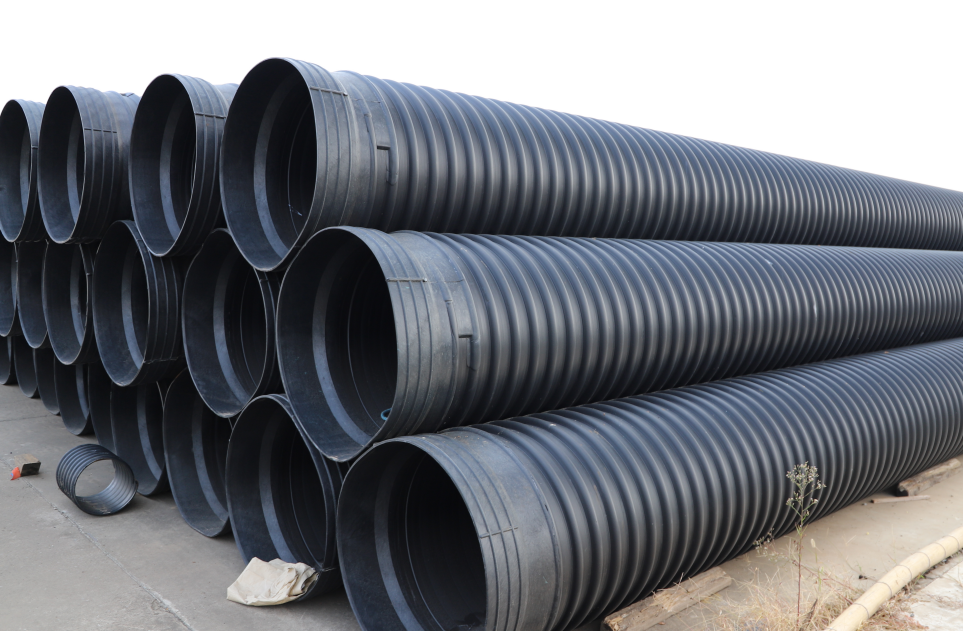

Introduction to AD HDPE steel strip reinforced spiral corrugated pipe: The composite of each layer of the

steel strip pipe is carried out in the molten state of plastic; it is completely different from the secondary melt molding of the wound pipe (hollow wall pipe), so the layers are completely bonded, and the fastness is very high. The surface of the steel strip is specially pretreated to enhance the anti-corrosion ability of the steel and the adhesion between the steel and the plastic, and improve the peeling strength. In the state of full melting of the plastic raw materials, the overall structure of the pipe is firm and reliable. Due to the use of special materials and processes, both the anti-corrosion problem of the steel plate and the adhesion between the steel plate and the PE material are solved, so that the service life of the pipe is the same as that of the pure plastic pipe, which is guaranteed to be more than 50 years. It can be connected by electric hot melt connection, heat shrinkable belt connection, internal and external extrusion welding or a combination of various connections, and the connection is firm. Reliable connection can make the pipeline achieve zero leakage. HDPE steel belt reinforced spiral corrugated pipe is made of U-shaped steel belt composite PE material, which makes the pipe greatly improve the ring stiffness without increasing the cost. The strength is greatly improved than that of wound pipe and carat pipe under the same weight. It can solve a series of problems such as heavy load, and the advantages of large diameter pipe are more obvious. The diameter of the production pipe is from DN300mm to DN2400mm, and the ring stiffness is maintained at more than 8KN/m2, which is lighter and stronger than cement pipe and other plastic pipes.

Chinese name: Steel belt reinforced spiral bellows

Foreign name: Steel belt reinforced spiral bellows

Abbreviation: Steel belt corrugated pipe, steel belt pipe

Material used: U-shaped steel belt composite PE material

Second, the advantages of HDPE steel belt reinforced spiral corrugated pipe:

1, high ring stiffness

For ordinary buried water drainage plastic wall winding pipe, its maximum ring stiffness is difficult to exceed SN8, but the new structure of the pipe is easy to reach SN8, SN12.5 and SN16, or even higher. On the other hand, this steel pipe as the middle layer, the inner and outer layers of polyethylene plastic steel-plastic composite pipe corrosion resistance is also very good. Therefore, this composite anti-corrosion pipe can be applied to a variety of harsh environments. For example, in some coastal areas, due to the corrosive substances in the soil, the working life of concrete pipes will be very short, and it is hoped that corrosion-resistant plastic buried drainage pipes can be used. However, in the past, because there was no high ring stiffness product could not meet the design requirements, metal reinforced wound structure wall pipes can now be used.

2, Save material costs

In addition to these improved performance, another significant advantage is to save material costs. Compared with other plastic pipes of the same diameter and ring stiffness, steel belt reinforced polyethylene (PE) spiral corrugated pipes can save nearly half of the material consumption, and polyethylene only accounts for 2/3 of the overall weight of the composite pipe; in the situation of rising plastic prices, this is a very good solution to reduce material costs. The ring stiffness achieved after the thin steel strip is pressed into a steel rib far exceeds the effect produced by a very thick polyethylene structural layer. Proper design of the thickness and height of the steel rib can easily achieve the required ring stiffness. The function of polyethylene in metal reinforced winding structural wall pipes is corrosion resistance and wear resistance, so there are not many steel rib materials in metal reinforced winding structural wall pipes, and polyethylene materials do not need to be much.

3, the combination of steel and plastic

The key to the success or failure of metal reinforcement is to ensure that the steel-plastic bonding is firm. This requires that the steel can be firmly bonded to the plastic, and the separation between any two layers is not allowed. In order to obtain good bonding properties, we have done a lot of research and tests in the development process of the pipeline. The current process is to pre-coat the steel strip with a special resin as the intermediate layer between the steel and the plastic. In addition, the process temperature, pressure and cooling down must be strictly controlled, and the steel-plastic layers are fused perfectly at the right temperature. Another key point to achieve metal reinforcement is to protect the metal layer that is easily corroded. In the structural design of the pipe, the steel ribs are covered with inner and outer polyethylene. The inner and outer surfaces that contact the transported liquid and the surrounding soil and groundwater are covered with thick polyethylene layers. Therefore, the corrosion resistance and wear resistance of the metal reinforced wound structure wall pipe are guaranteed.

2, impact resistance: the pipe wall adopts "U" shaped structure, impact resistance, pressure resistance, the foundation does not break when it sinks, and the recovery after deformation is strong, and it has good adaptability to the foundation;

3, aging resistance: the pipe is usually black, can withstand the direct sun during storage and construction;

4, cold resistance: the pipe will not be frozen and cracked in the -60 ℃ environment;

5, light weight: easy to transport, convenient construction, is 1/8 of the weight of cement pipe, buried pipe only excavator, no need for large equipment;

6, easy connection: the pipe can be connected outside the trench first, and pushed into the trench with the excavator to reduce the project time and cost;

7, excellent wear resistance: wear resistance than steel pipe and cement pipe, strong transportation capacity of domestic water waste residue;

8, drainage circulation Superior performance: smooth interior, reduce friction, fast drainage speed;

9, economy: low construction, management and maintenance costs;

10, environmental impact: HDPE is a non-toxic raw material, harmless to land and other environments, and can be recycled.

11, good stability of the pipeline system: the circular outer tensile structure of the pipe not only increases the ring stiffness of the pipe, but also has the effect of root resistance, which solves the problem of tensile and top well caused by the longitudinal displacement of the pipeline.

12, completely reliable ring stiffness: Since the elastic modulus ratio of the two materials of steel and plastic is greater than 200, the weight ratio is greater than 7.85, so compared with pure plastic pipe, steel belt reinforcement is very easy to make the pipe (especially large diameter pipe) has enough safe and reliable ring stiffness and relatively high stiffness to weight ratio

4, HDPE steel belt reinforced spiral corrugated pipe application field:

Municipal engineering: buried drainage, sewage pipe;

Road engineering: seepage and drainage pipes of railways and highways;

Industrial: widely used in industrial sewage pipes;

Construction engineering: building rain pipes, underground drainage pipes, sewage pipes, ventilation pipes, etc.; landfill sewage collection pipes;

Large ports, wharf projects: large airports, ports, wharf projects drainage, Sewage pipes, etc.;

Sports venues: water seepage and drainage pipes in golf courses, football fields and other sports venues;

Water conservancy projects: water source pipes, irrigation pipes and the use of water transmission and drainage in hydropower stations;

Mine: mine ventilation, air supply, drainage, mud pipes;

Communication pipes: railway, highway communication, communication cable, optical cable protection pipes;

Water storage system: water storage system that intercepts slow water flow;

Agricultural engineering: farmland, orchards, tea gardens and forest belt drainage and irrigation; seawater conveyor pipes.

Wuhan steel belt pipe, Hubei steel belt reinforced spiral corrugated pipe can contact us.

Source: Hubei Yuan Building Materials Co., Ltd., welcome to share! Hotline: 17399989993