1. Construction steps and precautions

Step 1: Power supply, welding machine selection

Power cord should be selected within 100 meters 6 square millimeters, before welding, you need to choose the appropriate welding voltage according to the identification parameters on the pipe fittings, there are two kinds of voltages of 220 volts and 380 volts, be sure to check clearly before use

Step 2: Blanking

Cut the pipe according to the required length to ensure that the port is perpendicular to the pipe axis

Step 3: Section grinding

After the pipe is cut, it needs to be polished by an angle grinder to make the section flat, which is conducive to improving the sealing quality

Step 4: Seal

Use a hot air welding torch or a plastic extrusion welding machine and a PE electrode to seal the cutting surface of the steel wire and rubber layer, and must cover all the exposed steel wire. Note: Hot air welding torch To face the cutting surface and the electrode at the same time heating,

Step 5: Mark number

mark the depth of the pipe socket on the pipe to ensure that the pipe socket is in place

Step 6: remove the oxide layer, clean the welding area

use hanging to remove the pipe end oxide layer, and wipe the surface of the welding area with a clean towel. The welding surface is not allowed to have mud, oil and other dirt. Note: If there is oil at the end, use alcohol solution to deal with it.

Step 7: Socket connection

When the socket is inserted, first set the pipe on one end of the pipe. When it is slightly tight, use a rubber hammer to gently tap, and the other end is padded with wood. Use a hammer to hit or hand-cranked gourd to assist the socket in place.

Note: When the socket is inserted, a round object can be padded under the pipe for easy installation. When the large-diameter pipe is installed tightly, it can be installed with a tensioner. Special attention should be paid to ensure the cleanliness of the installation surface during Before welding, the pipe should be padded with a support.

note that in order to prevent the pipe fittings and pipes from falling during welding, the pipe fittings or pipes should be supported with wooden blocks before welding.

Step 9: Electrofusion Welding

Operation Steps:

Select the appropriate welder according to the pipe diameter specification. When the pipe specification is less than or equal to 300 millimeters, the output voltage of the welder should be 200 volts. When the pipe specification is greater than 300 millimeters, the output voltage of the welder should be 300 volts. According to the diameter of the terminal latch on the pipe fittings, choose the corresponding fused joint. Insert the cable into the welding machine to turn on the power supply, turn on the machine power switch, and enter the parameter interface. According to the pipe fitting parameters, set the corresponding parameters on the equipment through the up and down cursor. Then insert the two electric fusion joints into the terminal block of the pipe fitting respectively, and press the OK button to start welding. Tenth step: cooling

after the welding is completed, the cooling process to let the welding in a natural state, and should ensure that the cooling process is not subject to any external force, after cooling to move

Hubei AD Building Materials Co., Ltd. Reminder, the welding process precautions:

1, if the voltage is unstable, stop welding immediately,

2, if the welding process power failure, not allowed to secondary welding,

3, before welding according to the pipe logo, accurate input welding parameters

4, pipe in the cooling down prohibit movement, bending, to avoid pipe and pipe separation or leakage phenomenon,

5, rain and snow weather welding, when the temperature is lower than minus ten degrees Celsius welding is prohibited.

Second, pressure test acceptance

1, pressure test acceptance can refer to the water supply steel mesh skeleton plastic composite pipeline engineering technical regulations, and buried plastic water supply pipeline engineering technical regulations.

2, the pipeline can be backfilled after passing the pressure test.

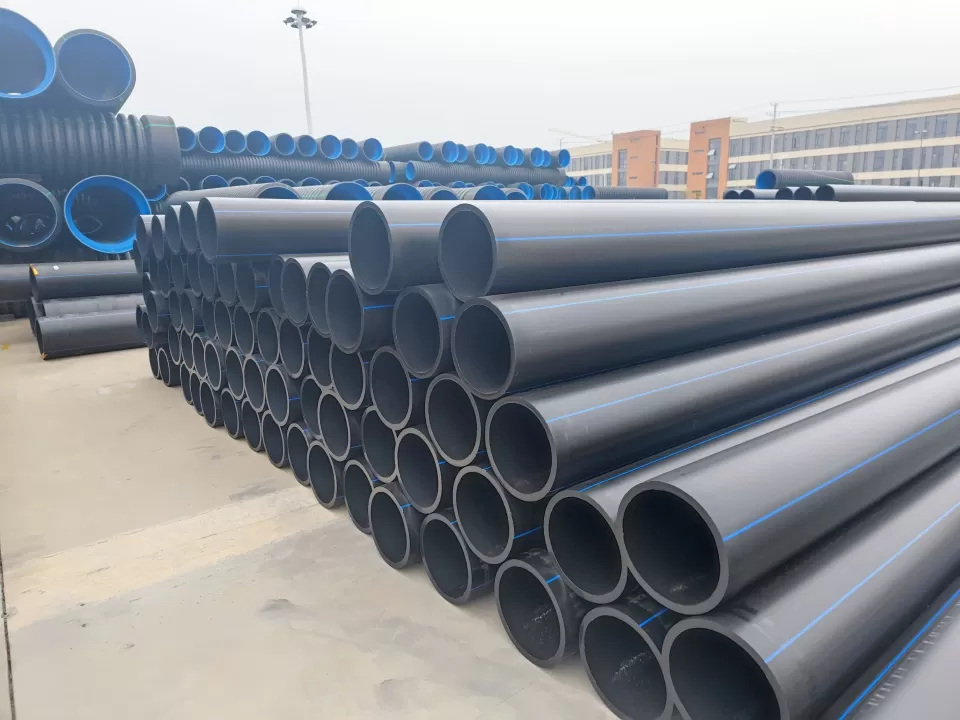

If there is a steel mesh skeleton pipeline contact hotline 17399989993, Hubei AD Building Materials Co., Ltd. sells AD pe pipe, AD pe steel mesh skeleton composite pipe.